2019年12月13日

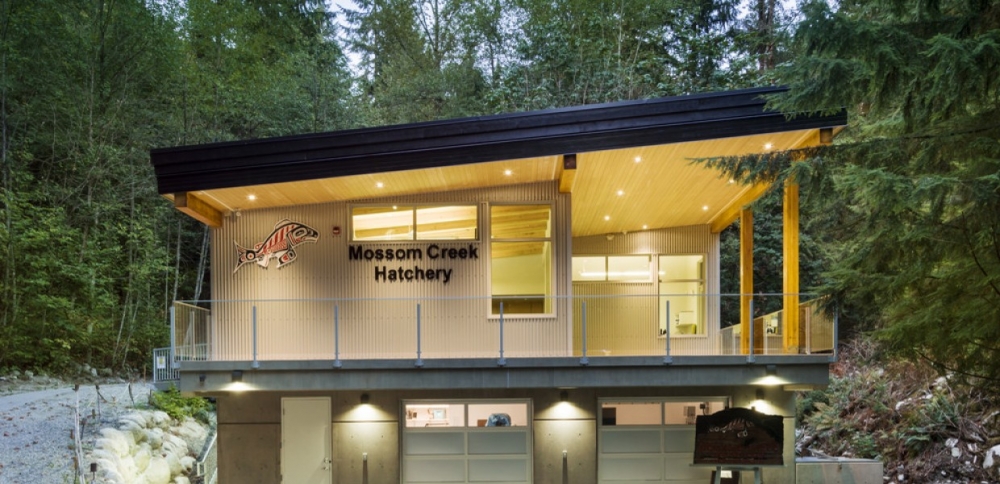

This rebuilding project focused on the environment, sustainability, and education. Due to its remote location from the city water supply, the building was required to be built non-combustible due to its destruction caused by an earlier fire.

The two-story structure houses a hatchery on the ground floor and an education center upstairs. The ground floor is a concrete construction with no windows, for reasons of security and fire safety. The hatchery building features a large deck over a portion of the lower hatchery, forming the roof in this area. Since the hatchery is fully enclosed, the skylight had to be fire-rated glass.

Contraflam LiteFlam provides a walkable, one-hour fire separation from the upper structure to the lower hatchery, serves as a light source and allows visitors to catch an insight into the hatchery. Vetrotech was pleased to donate this solution in order to prevent future damages to the hatchery.

The walkable insulated glass unit has a 60-minute fire-resistive rating and is part of Vetrotech’s very own Contraflam product range. It is a light-weight application with excellent energy saving values, which contribute to the project’s sustainability targets. A ceramic frit pattern on its surface provides additional anti-slip protection while still allowing visitors to see the hatchery from the upper deck and, on the contrary, the world outside from the space indoors.

PROJECT KEY ACHIEVEMENTS

• Vetrotech donated the glass as pro-bono project

• Daylight / energy savings

• Provides protection of possible combustion

PROJECT KEY CHALLENGES

• Very wooded area that needs protection from elements

• Natural light entry where the fish are kept

• Rebuilding project recovered from a fire

PROJECT STAKEHOLDERS

• Building owner: The Burrard Inlet Marine Enhancement Society

• Installer: Many volunteers

• Architect: OMB Architects