ZirGrip®

Part Number

- Name Type D50

- ZirGrip-1 - 1.5 micron

- ZirGrip-3 - 3.0-4.0 micron

- ZirGrip-10 - 12.0-14.0 micron

- ZirGrip-30 - 90.0-95.0 micron

Specification

Zirconium dioxide is an abrasive material frequently used in friction applications. When incorporated into a brake pad formulation, zirconia plays the role of a friction modifier that also reduces brake wear. For brake pad applications, Saint-Gobain ZirPro offers ZirGrip®, a unique zirconium oxide powder. The only powder of its kind on the market today, ZirGrip is composed of particles with dendritic morphology, which enable better cohesion between the polymeric resin and zirconia particles.

Fine powders with narrow particle size distribution

ZirPro supplies three types of ZirGrip powders (ZirGrip-1, ZirGrip-3 and ZirGrip-6) with d50 ranging from 1.5 µm to 7 µm that provide more options to achieve friction properties. All ZirGrip powders have a narrow particle size distribution to prevent resin starvation or rotor scratching.

High-quality powders for consistent high performance

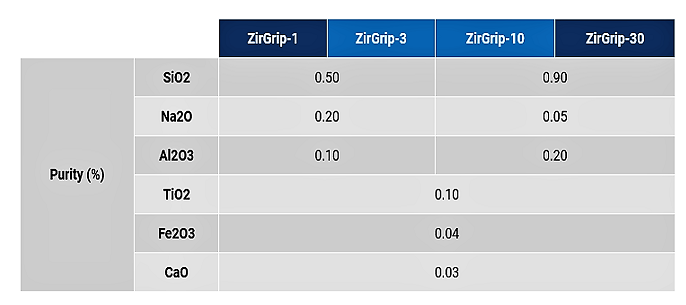

ZirGrip high chemical purity powders feature low concentrations of titanium oxide, iron oxide and alumina, providing stable and consistent brake pad performance. ZirGrip powders are manufactured in France using the highest standards of production to ensure continuous supply and consistent quality. In addition, ZirGrip powders comply with the most stringent environmental regulations.