Key Awards for Abrasives Team

SGRS Abrasives R&D team got 4 National or Global key awards in the past one year which shows high innovation R&D works and big contribution to business.

2024-04-24: Gear power honing got runner-up presentation during 2024 Research Seminar in Paris.

2024-06-12: SGRS Awarded 2024 China Technology Trade Innovation Practice Case in Shanghai.

2024-12-19: Electronic glass grinding new product got SG Surface Solution Our Customer Award.

2025-01-06: Litchi technology got the 2nd edition Innovation Awards for the New Horizon Innovation category in SG Group in Paris.

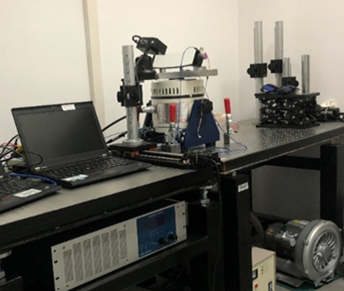

New ENC Test Rig with Climate Control for Sliding Solutions

Our new test rig with climate control is designed specifically to ensure precision, accuracy, and reliability in the evaluation of sliding solutions for our bearing products. Equipped with the advanced climate control technology, it empowers out engineers to assess durability, friction, or performance of the sliding assemblies under tailored climates conditions with exceptional accuracy. From extreme temperatures to varying humidity levels, this test rig offers precise control over every environmental variable replicating real-world scenarios and allowing for comprehensive testing under a wide range of operation conditions for the development of sliding systems.

New Capabilities in ENC R&D Aim to Accelerate Automotive Innovation

ENC R&D established 2 additional test capabilities beyond current various types of test competency to support innovation in the automotive market.

HUD (Head-up Display) test platform is a collaboration between ENC R&D and CRL to combine a multifunctional vibration platform and laser technology. The new test system will help to benchmark bearings solutions with existing ones in a HUD unit in terms of NVH performance and lifetime to accelerate co-development with customers for high end wind shield HUD.

High speed rotary test platform is a versatile system to evaluate sealing performance in critical applications e.g. transmission in powertrain for traditional combustion engine and EV. With max speed of 20K rpm and wide temperature range from -40~120C the new system will provide solid and unique test data for researchers to develop innovative sealing solutions to automotive market.

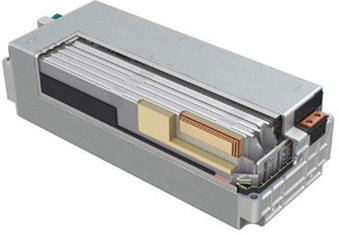

The electric vehicle battery application testing laboratory located in Saint Gobain R&D (Shanghai) maintains continuous growth to support the certification work of Tape Solutions business in global customer business projects. The laboratory has established comprehensive mechanical, aging, electrical, and thermal testing capabilities, and is gradually conducting battery cell and module level testing. We provided systematic research on customer design certification testing, materials, and applications, and received on-site visits and technical discussions from important clients, including battery manufacturers, automotive OEMs, and research institutions.

The new generation of Saint Gobain compressed foam products for electric vehicle batteries have been mass-produced, with the product brand PF100. With the high energy density requirements for batteries in terminal electric vehicle applications, the space reserved for foam between battery cells is becoming less and less. This new product can provide a wider compressible range and the advantage of a slower increase in compression rebound force within the compressible range, meeting the needs of high energy density battery packs. On the basis of this product, Saint Gobain has developed high thickness, low density PF100OC, and high hardness PF200 products, which are suitable for the performance requirements of more battery cells.

Life sciences

Extractables competency developed within life sciences and CRL, has been delivering plenty of test methods, and tons of data and reports to bioprocess solution business. These test methods are targeting for identifying and quantifying ppm level of organics and inorganics. The high quality reports give more and more positive impact on product promotion and business growth.

The strong collaboration among life sciences plants, quality, business teams and R&D, allow us to be more and more competitive for our products, and extractables capabilities when comparing to our competitors, and allow us to give more and more technical impact on global industry standards.

And all these are dedicated to make our life better and safter.

New BPS application lab in R&D to support product application

Saint-Gobain life sciences create customized single-use solutions by development and integration of innovative materials and components. New BPS (Bio-process solutions) application lab was developed in Shanghai R&D center to support the biopharmaceutical and cell therapy market success. Chemical compatibility test, hold-up volume test, film analysis and integrity test capability were built to align with our internal or external customer needs. As customer valued proactive partner, tubing life test, tubing burst pressure test, tubing fatigue and failure analysis strengths were enhanced in new application lab for critical fluid management strategy.

New silicone tubing launch

Saint-Gobain Life Science's new silicone pump tube product VersilonTM SCN-1000 was launched in Shanghai R&D center. The high-speed pump tubing is silicone-based tubing with high pumping performance which is of great compatibility with high-speed peristaltic pumps. These features enable the high-speed pumping tubing can be applied for critical fluids transfer applications that requires long service time and high precise flow rate control, e.g.spraying drones in precision farming

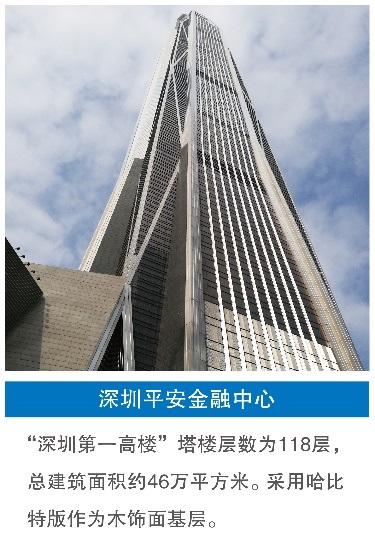

哈比特™ Gypsum-based High strength fiber board

哈比特™ gypsum-based high strength fiber board was launched in China in 2016. Thanks to its excellent Class A fire reaction, E0 formaldehyde emissions, and high-strength of nail pull, this product has become a popular alternative to plywood panel as an upgrade for interior wall lining. 哈比特™ gypsum-based high strength fiber board is widely used in hospitals, schools, commercial buildings, theaters, museums, and other structures.